The ultra-thin electrolyte making process is revolutionizing the landscape of battery manufacturing, particularly in the realm of solid-state batteries. With electrolyte thickness controlled to less than 20μm, this innovation enhances battery performance and longevity. Companies like LEAD are at the forefront of this transformation, offering advanced solutions that cater to the growing demand for efficient and reliable energy storage.

Advantages of the Ultra-Thin Electrolyte Making Process

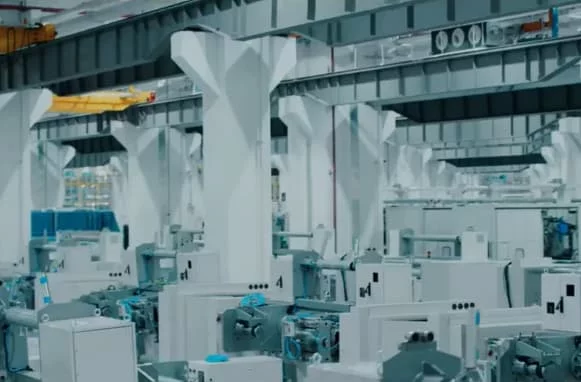

The ultra-thin electrolyte making process provides significant advantages over traditional methods. By achieving a thickness of less than 20μm, the process not only improves ionic conductivity but also reduces the overall weight of the battery. This is particularly beneficial for automotive applications, where lighter batteries can enhance vehicle efficiency and performance. LEAD’s all-solid-state battery manufacturing equipment is designed to optimize this process, providing a full solution that includes battery cell production, packaging, and testing equipment. This comprehensive approach ensures that manufacturers can streamline their operations and enhance product quality.

Why Choose LEAD for Your Battery Manufacturing Needs?

Choosing LEAD means partnering with one of the leading smart manufacturing companies specializing in battery technology. With a focus on smart equipment production solutions, LEAD’s offerings encompass everything from battery cell creation to final testing. Their expertise in the ultra-thin electrolyte making process ensures that clients benefit from cutting-edge technology and reliable performance. By opting for LEAD, manufacturers can take advantage of a complete solution tailored to meet the specific needs of automotive battery production.

Conclusion

The ultra-thin electrolyte making process is a pivotal development in solid-state battery manufacturing. LEAD stands out as a trusted partner, providing innovative equipment and full solutions for the evolving energy storage market.