For senior engineers and procurement executives in the EV and industrial sectors, the drive to consolidate complex assemblies involves more than just geometry; it requires a strategic choice between structural rigidity and functional layering. When optimizing for automotive injection molding, selecting the correct consolidation method—insert molding or overmolding—is critical for meeting weight reduction targets, waterproofing standards (IP67/68), and simplifying supply chains. This guide analyzes technical distinctions to help you determine the optimal pathway for unitizing electronic assemblies.

Strategies for Component Consolidation and Integration

To replace multi-part steel assemblies with unitized thermoplastic solutions, engineers must evaluate whether the priority lies in encapsulating rigid hardware or applying functional secondary layers.

Structural Integration via Insert Molding

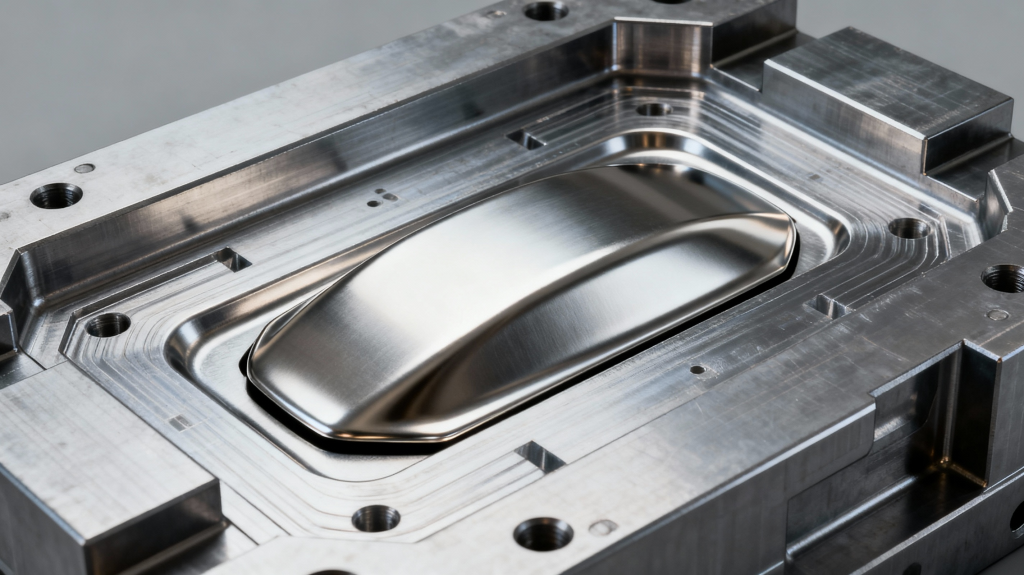

Insert molding serves as the definitive method for structural consolidation in the plastic injection molding automotive industry. This process involves placing pre-formed components—such as stainless steel fasteners, brass bushings, or conductive circuits (In-Mold Electronics)—into the mold before resin injection. By encapsulating these elements within a high-strength engineering thermoplastic matrix, manufacturers can eliminate secondary assembly steps.

Historical data from automotive chassis applications indicates that replacing traditional stamped steel brackets with insert-molded thermoplastic composites can yield a 30% to 50% weight reduction while maintaining load-bearing capacity. Furthermore, this method directly addresses tolerance stacking issues. By securing terminals and mounting points within the automotive injection mold itself, the variance associated with manual screw insertion is removed. For high-voltage EV connectors, vertical injection presses equipped with 6-axis robotics ensure insert placement accuracy within ±0.02mm, preventing insert drift during the high-pressure injection phase.

Functional Sealing with Overmolding

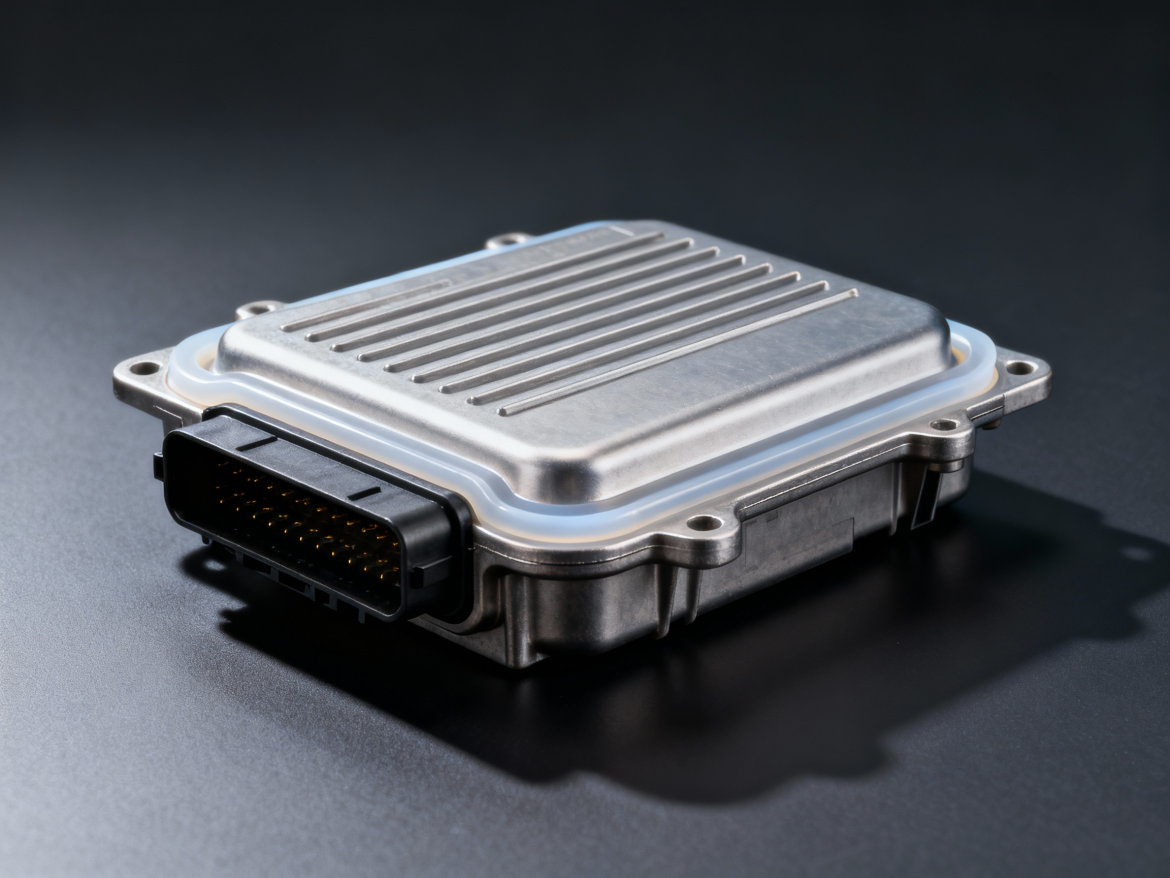

While insert molding secures the core, overmolding excels in adding functional versatility, particularly for environmental protection. This technique is essential for automotive rubber injection molding, where a rigid substrate (often glass-filled nylon or PBT) receives a secondary shot of Liquid Silicone Rubber (LSR) or Thermoplastic Elastomer (TPE).

For electronic control units (ECUs) requiring hermetic seals, overmolding creates a chemical bond between the substrate and the seal, superior to mechanical gaskets. Achieving IP67 or IP68 ratings relies on optimizing the bond between dissimilar materials. Technical analysis shows that utilizing specialized adhesive promoters in multi-shot (2K) molding can achieve peel strengths exceeding 15 N/mm, ensuring seal integrity under thermal cycling from -40°C to 125°C. This capability allows injection molding automotive industry suppliers to deliver “housing-as-seal” solutions, removing the failure points associated with manually installed O-rings.

Process Optimization and Validation

Achieving production efficiency requires advanced thermal management and rigorous digital simulation to mitigate defects in complex, multi-material components.

Thermal Management and Lightweighting

Consolidating parts often results in variable wall thicknesses, which can lead to warpage. To counter this, advanced plastic injection molding for automotive applications utilizes Micro-Cellular Foaming technology. By injecting supercritical gas (nitrogen or carbon dioxide) into the melt, resin density is reduced by 8-12% without compromising tensile strength. The internal gas pressure prevents sink marks in thick sections, a common challenge in consolidated housings.

Cycle time is another critical metric. Implementing conformal cooling channels—often fabricated via 3D metal printing—allows cooling lines to follow the complex contours of an insert-loaded part. Case studies demonstrate that conformal cooling can reduce cycle times by 20% to 30% compared to traditional straight-line cooling, significantly lowering the Total Cost of Ownership (TCO) for high-volume production.

Simulation and Quality Control

Before steel is cut, pre-production validation via digital twins is mandatory. Rheology software simulates fiber orientation in fiber-reinforced composites to predict anisotropic shrinkage. For automotive injection molding suppliers, this predictive capability is vital when designing gates for insert-rich geometries to avoid “racetracking” effects or air traps around metal contacts.

In production, closed-loop process control monitors cavity pressure curves in real-time. Automated systems can compensate for viscosity variations in recycled materials (PCR) or batch-to-batch resin fluctuations. Adherence to IATF 16949 standards ensures that every consolidated assembly meets strict automotive safety protocols, with full traceability from raw resin to the final electronic unit.

Livepoint Tooling: Precision Manufacturing for Automotive Systems

Livepoint Tooling leverages over 23 years of expertise to deliver high-precision tooling and molding solutions for global automotive OEMs and Tier 1 suppliers.

IATF 16949 Certified Production: Our facilities operate under strict automotive quality management systems, ensuring consistent repeatability for safety-critical components, from interior trims to under-the-hood electrification systems.

Advanced Tooling Capabilities: We specialize in complex mold designs, including multi-cavity, hot runner systems that enable seamless insert and overmolding execution. Our in-house tooling shop allows for rapid engineering changes and maintenance.

Comprehensive Validation: Equipped with CMM inspection, CT scanning, and electrical performance testing labs, Livepoint validates every dimension and seal interface to guarantee compliance with rigorous industry standards.

Global Reach: Headquartered in Shenzhen with a global service footprint, we support the American market with efficient logistics and engineering collaboration.

Conclusion

Whether your project requires the structural rigidity of insert molding or the hermetic sealing of overmolding, Livepoint Tooling provides the engineering depth to execute complex consolidations. Contact our engineering team today to conduct a manufacturability review and identify the optimal strategy for your production goals.