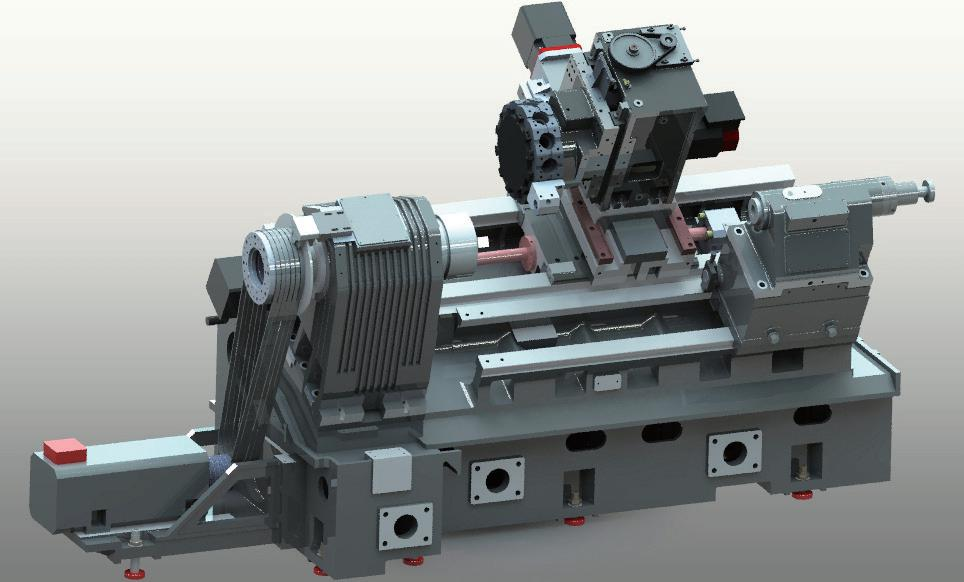

CNC machining plays a vital role in modern manufacturing, offering precision and flexibility for diverse industrial applications. Among the various types of CNC equipment, CNC turning and milling machine and mill turn cnc machine are two prominent categories. Leichman provides advanced solutions in this field, including the Leichman LK-750MY CNC Turning and Milling Lathe, designed to address complex metalworking tasks with efficiency and accuracy.

CNC Turning: Precision in Rotational Operations

CNC turning primarily involves rotating the workpiece while a stationary cutting tool shapes its exterior or interior surfaces. This process is highly suitable for producing cylindrical parts, such as shafts, bushings, and threaded components. They ensure that their CNC turning and milling machine offers reliable rotational precision, utilizing high-quality components and robust construction. The design of the Leichman LK-750MY CNC Turning and Milling Lathe allows operators to achieve consistent surface finishes and tight tolerances, making it ideal for metal processing industries and specialized manufacturing lines.

CNC Milling: Complex Material Removal

Unlike turning, CNC milling uses rotating cutting tools to remove material from a fixed workpiece, creating intricate shapes and surfaces. This method is particularly useful for components with flat or irregular geometries. They provide mill turn CNC machine solutions capable of performing multiple milling operations with integrated turning features. The Leichman LK-750MY CNC Turning and Milling Lathe exemplifies this versatility, combining milling and turning functions in one platform to optimize workflow, reduce setup time, and support both standard and custom projects.

Integrated Solutions for Diverse Industrial Needs

Manufacturers increasingly seek equipment that can handle various machining tasks within a single unit. They focus on delivering machines that are adaptable, durable, and capable of meeting non-standard requirements across metal processing, mechanical equipment, and industrial trading sectors. With quick technical support, proactive maintenance, and full-cycle project assistance, Leichman ensures that their CNC turning and milling machine supports efficient production, lower inventory pressure, and shorten cross-border procurement cycles for EPC contractors, international agents, and industrial clients.

Conclusion: Enhancing Efficiency with Leichman

By understanding the differences between CNC turning and CNC milling, industrial operators can select the appropriate machinery for their manufacturing needs. They offer the Leichman LK-750MY CNC Turning and Milling Lathe as a versatile, high-performance solution that integrates turning and milling operations. With a commitment to precision, adaptability, and comprehensive support, Leichman helps clients improve productivity and meet complex industrial demands effectively.